FROM IDEAS TO PRODUCTS

METZNER ENGINEERING is a company for engineering, design and production for the mechanical- as well as for the vehicle production industry, founded and led by Dipl.-Ing. Simon Metzner.

An extensive experience plus a large network of partners and suppliers guarantees a reliable, competent and holistic processing of projects.

The own production with modern CNC machining centers ensures prototype and series production.

Through a close integration of design and manufacturing, METZNER Engineering tackles complex tasks with exceptional efficiency.

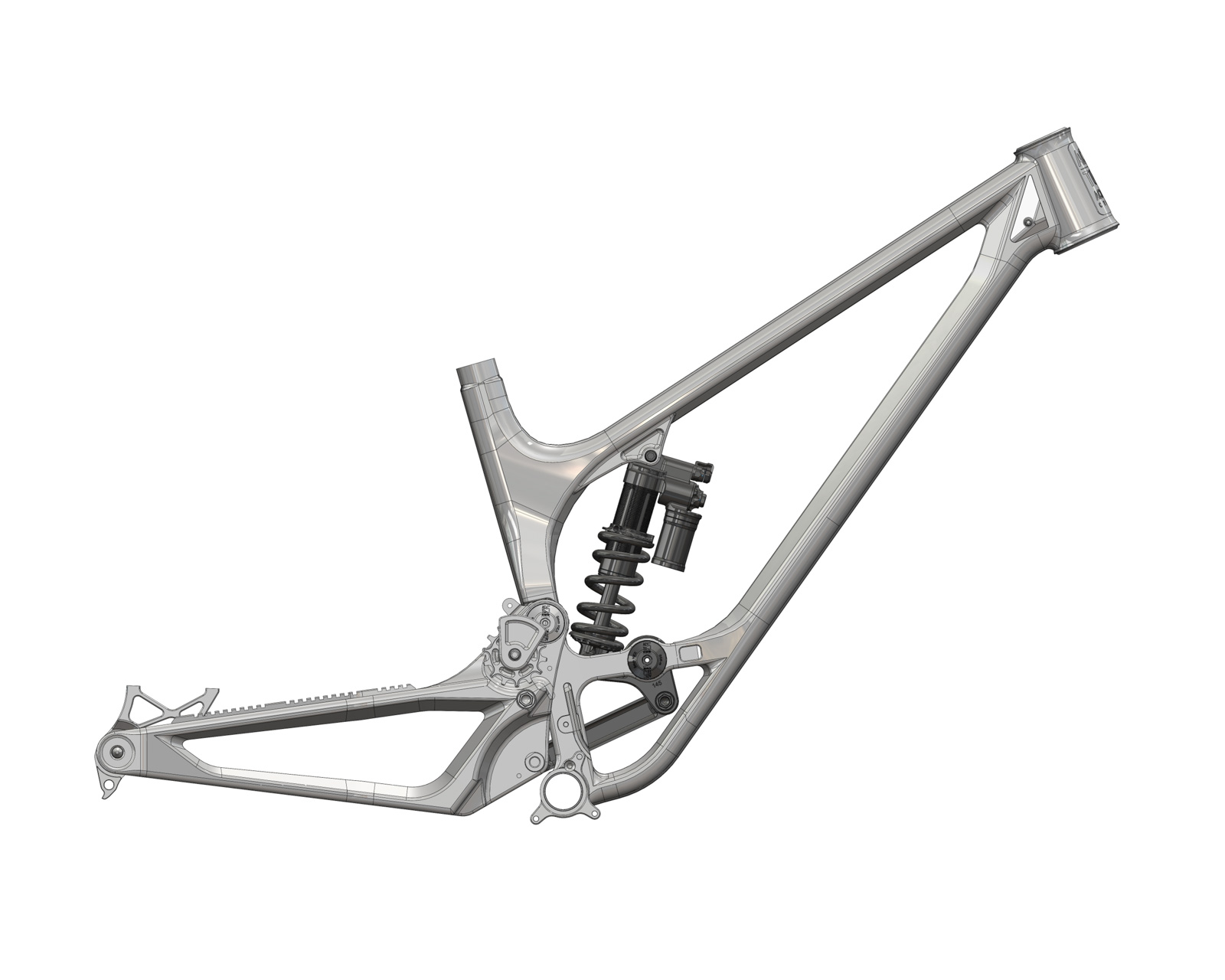

Under the brand ACTOFIVE Cycles, METZNER Engineering is the only company worldwide that develops and produces fully CNC-machined bicycle frames from thin-walled shell components – commercially and in series production. METZNER Engineering employs state-of-the-art CNC manufacturing, precise measuring systems, and cutting-edge adhesive technologies to ensure the highest levels of quality and reliability.

REFERENCES AND PARTNERS

ENGINEERING

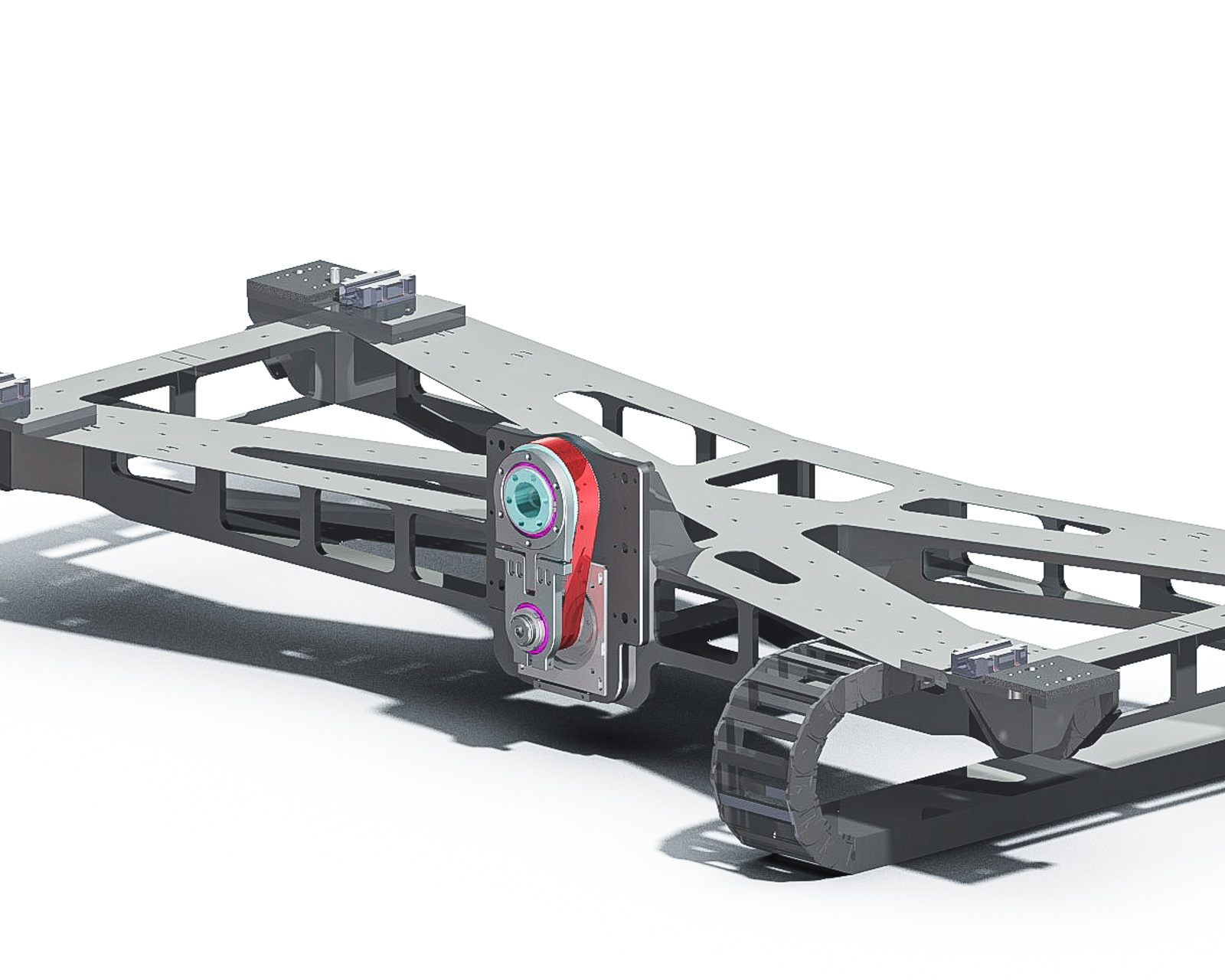

With an extensive experience in mechanical engineering and vehicle production industry METZNER ENGINEERING acts with engineering tasks from the first sketch up to production control.

vehicle production industry

full suspension MTB-frame with high pivot point and progressive kinematics

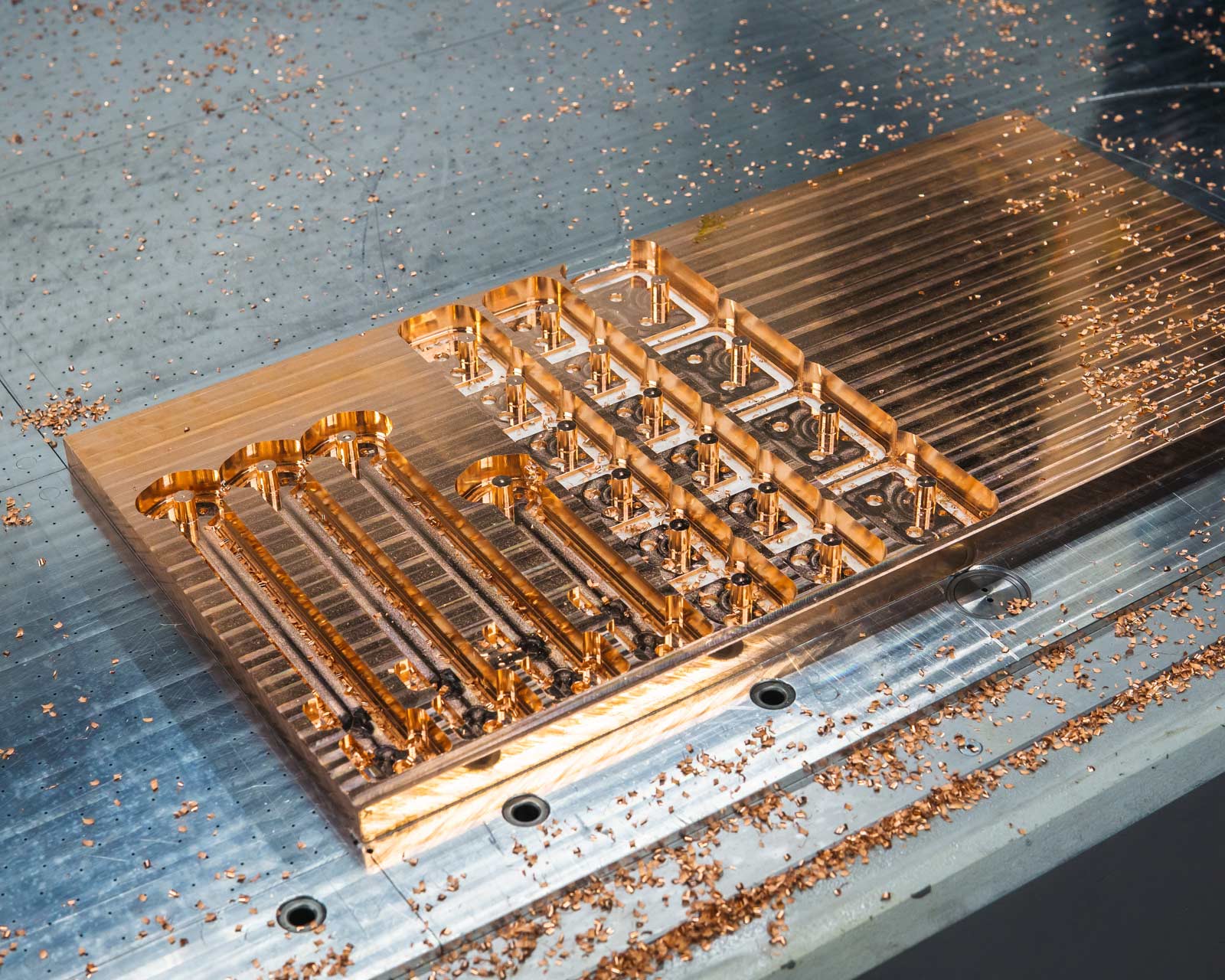

PRODUCTION / CNC-MILLING

On a modern CNC milling center with vacuum table and powerful 2,5-D and 3-D CAM-software, METZNER ENGINEERING produces flat parts out of aluminum or plastic materials, as for example:

- filigree or small parts, which are difficult to clamp on standard vacuum tables

- parts with high quality requirements and no rework

- large parts up to 3,000 mm by 2,000 mm

- parts out of thicker plates, for example main plates with threads holes and precision bores

- parts with high quantity

- prototypes or small batches

- parts with 3-D shapes, for example mould or tool construction

Projects

METZNER Engineering GmbH

Meschwitzstraße 21

01099 Dresden

Phone: +49 (0)152 06 49 39 85

Mail: info@metzner-engineering.de

Web: www.metzner-engineering.de

Managing Director: Dipl.-Ing. Simon Metzner

Trade Register: Amtsgericht Dresden, HRB 35875